For CNC router machine, the cutting tool will be fitted into spindle and by using rotating method to start the cutting process. Spindle will rotate with suitable speed to obtain high quality products. The cutter looks like a drill bit and is spun by a motor called spindle. Unlike a drill bit, a router bit is designed to cut from the sides as well as the tip.

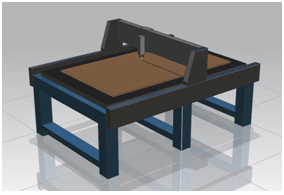

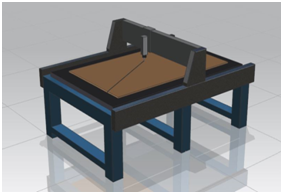

By precisely moving the cutter through material, a CNC tool can create virtually any pattern or shape and able to do it in materials such as wood, plastic, foam, aluminium and many composites. The CNC works on the Cartesian coordinate system (X, Y and Z) for 3D motion control. Parts of a project can be designed in the computer with a CAD/CAM program, and then cut automatically using a router or other cutters to produce a finished part.

A CNC router machine can cut workpiece in the same way you would with a saw. It can cut in the X or Y axes (horizontal or vertical) direction.

It can cut on any diagonal (combination of X and Y axes direction). It can also make the cut at any depth, or even at varying depths depends on feed rate, type and thickness of material selected.

A CNC router can also cut circles and holes. These can be any size from as small as the size of the cutter itself to the size of the whole table. It can also cut arcs, ellipses and curves at any depth or at varying depths within the cut.

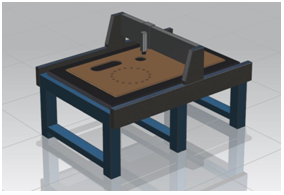

Vacuum System Operation

The heart of the vacuum system is the vacuum pump. In order to hold down material such as wood, MDF and plastic to the router table using vacuum, the performance of the vacuum pump has to be taken into consideration. Air that will be drawn by the pump will first travel through a spoilboard, then passed through different valves and plumbing fittings and finally through a pipe or tube to the pump itself.

In previous section, we already explained about the various types of vacuum pumps. To understand more detail, the following video will show you how a pump is installed to the CNC router machine and hold the parts using the suction of the sacrificial board to the table surface by the pump.