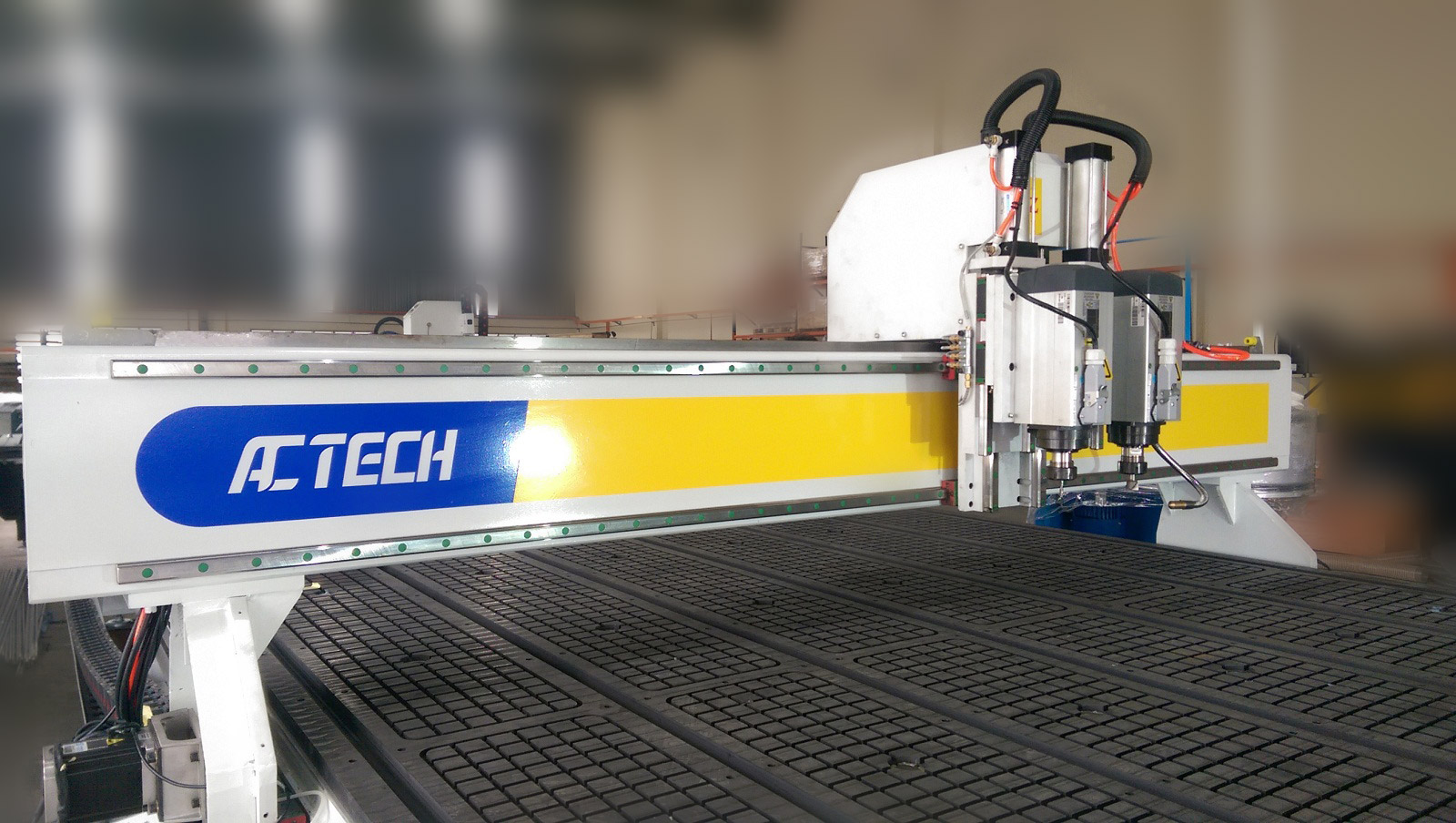

CNC RouterFor woodworking and sign making

A CNC router is a computer controlled machine in which the router or spindle mounts. The tool paths are controlled via computer numerical control system. The CNC Machine can be a moving gantry style, where the table is altered and the router spindle moves over workspace table, or fixed bridge design, where the table moves underneath the router spindle.

CAD/CAM software programming is used to model the part that be created in the computer and then create a tool path for the machine to cut the part. The CNC moves along three axes (X-Y-Z). Most CNC routers have a three motor drive system utilizing either servo or stepper motors. More advanced routers use a four motor system for added speed and precision.

Advantages

Automation

CNC cutting can be entirely automated to handle hundreds or thousands of projects. If you have one design that needs cutting over and over again, a CNC cutter will handle this with ease. It could be automotive parts or plastic components. In fact, the machinery can be left overnight and will automatically keep the production line moving. All it takes is some simple programming in the outset and it’ll run effectively.

Precision and accuracy

Thanks to this automation, you can guarantee precision and accuracy. So long as the designs have been drawn to a precise scale measurement, the CNC router will take care of the rest. Previously, it would be left in the hands of a hand-held machine that is susceptible to mistakes. With a cutting machine, that is no longer a problem.

Safety

As the cutting machinery is no longer reliant on human control, it is inherently safer. CNC routers are complete with safety features to guard against accidents. If a problem develops with the machinery, it will simply damage itself, rather than inflicting harm to others. The less hand-held cutting devices in operation, the safer the business.

Lower manpower costs

We’ve already touched on the automation abilities of these machines. It means that less manpower is needed in the cutting process. A smaller team can program and monitor the robotics, alleviating the strain on human resources. It is also possible to employ lower skilled workers. The precision and skilled work is taken care of by machines, so they can be run at a lower cost.

Flexible and adaptive

The best thing about new engineering technology is the inherent flexibility. CNC routing can adapt to any project at the click of a button. If it can be programmed, it can be cut! This follows a familiar theme in the manufacturing and engineering world. The likes of laser technology and 3D printing have flexibility at their heart. These technologies allow their operators to change and alter the product easily. It means they can work with a myriad of business sectors and open themselves to new territories.