WHAT DOES CNC MEANS?

Computer Numerical Control

“C” stands for the computer and “NC” stands for the numerical control. This means the function and motion of a machine tool is controlled by computer with the design is converted into program containing coded alphanumeric data.

All CNC machines have two or more programmable directions of motion called axes. An axis of motion can be linear or circular. Common linear axis names are X, Y, Z while for common rotary axis names are A, B, and C. These axes can be precisely and automatically positioned along their lengths of travel for the purpose to create the motion needed for manufacturing.

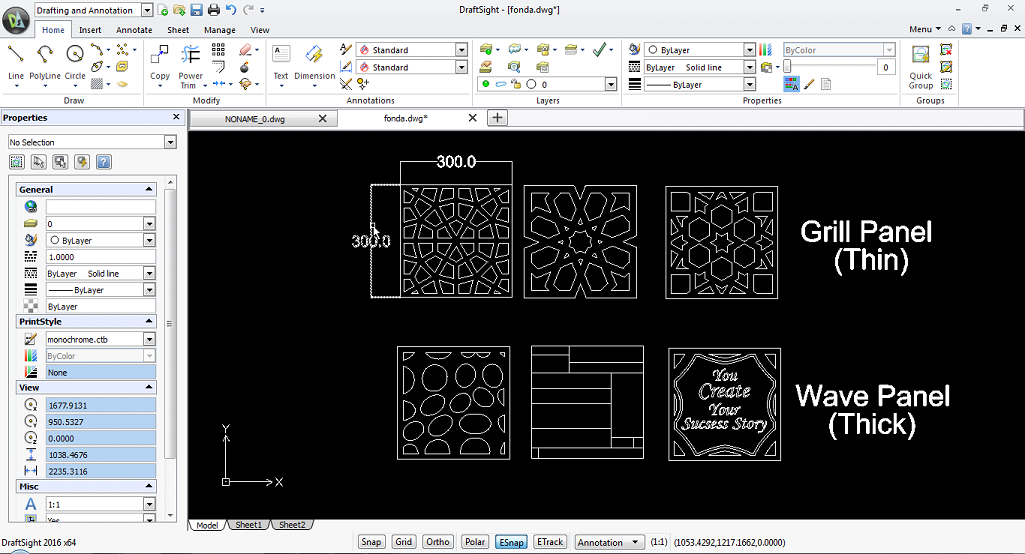

A design for a product is normally produced by the CAD software. Example of CAD software are AutoCAD, SolidWorks, DraftSight, TurboCAD, SketchUp and so on. It can help us to turn a 2D and 3D design into useful models and prototypes. From the small part of object to the whole body structure of the product, CAD software is the tool that can help us to build and customize designs from ground up. Furthermore, it can improve the quality of design, increase the productivity of designer, improve communication through documentation and create a database for manufacturing.

Generate a design using CAD software

After the design for a product is ready, the design is converted into programming. A CNC program is written in sentence-like format and the control will execute in sequential order. Special words is needed to communicate with the machine. For example, F for feed rate, S for spindle speed, X,Y and Z for motion of axis. When they are placed together, the words will make up a command. CNC control will read the command and interpret it. Then, it will give the instruction to the machine to produce the axis motion.

CNC program can be developed manually. However, due to the applications become more complicated, CAM software is used to simplify the programming process. CAM software is applied to the models and assemblies created in CAD software to generate toolpath and NC code to drive the CNC controlled machines. When the two are used together, this is generally referred to as CAD/CAM. CAM is the use of computer to assist all operations of a manufacturing plant which include planning, management, transportation and storage. The objective of this software is to create a faster production process, components and tooling with more precise dimension. Also, it can minimize the material waste which simultaneously reducing energy consumption.

Ucancam Engraving Software

Nowadays, a lot of CAD/CAM software are available in the market. Ucancam Engraving Software is one of the choice to be applied due to its easier cutting programming. Only a few clicks is needed and we can cut the material. Toolpath is calculated very quickly and accurately. Ucancam provides a Tools Library where users can choose, edit, add or delete a tool. Besides that, users can apply toolpath simulation to check whether toolpaths are valid and to preview machining results.

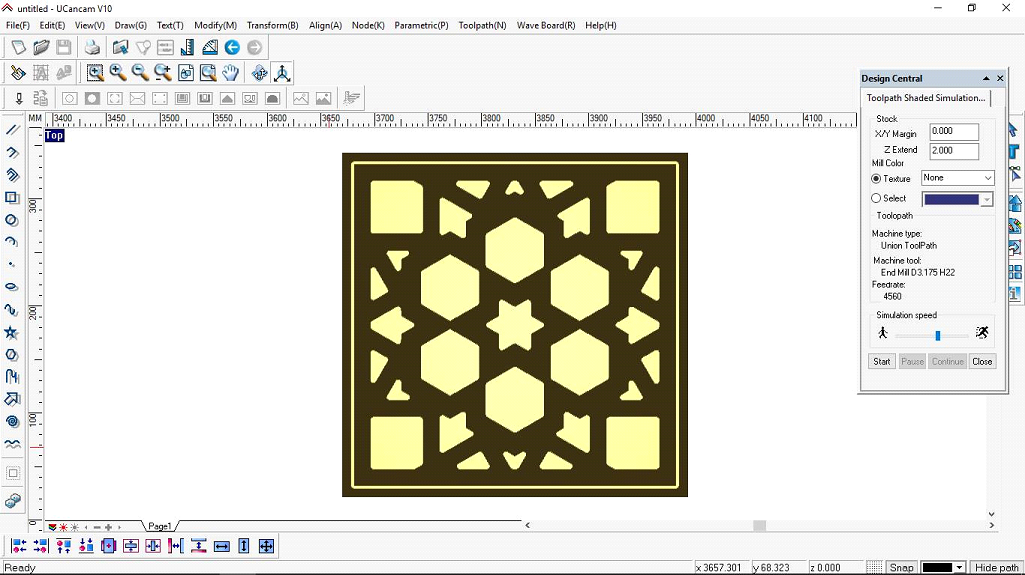

Ucancam Toolpath Simulation

These simulation functions are also useful to reduce trial cutting times and cut down machining costs and help users to get valid and effective machining results. Ucancam is widely applied in fields such as advertisements, exhibition, decoration, artwork, moulds, seal-making, signs, gifts, architectural moulds, wood working and so on.

History of CNC Router

Oscar Onsrud

In 1915, Oscar Onsrud invented the first air powered, high-speed spindle. A singular innovation which transformed an industry and fasten the speed to manufacture goods. Onsrud family still remain to design the CNC Router machine until now. Their greatest accomplishment is inventing an innovative spirit within his family’s legacy, passing the torch of engineering excellence from one generation to the next.

-

1915

Patternmaker & Woodworker

Before 1915, hand tool was frequently used by patternmakers and woodworkers. However, in 1915, the first handheld power routers which known as “Jet Motor Hand Routers” were invented by Oscar Onsrud and his son Rudy. Onsrud got the idea to create this machine when a rail road company decided to power the front light on a Steam Locomotive off of the waste steam from the engine.

-

1960

Development of CNC Machine

In 1960’s, CNC (computer numerical control) machines were developed and modified since the first CNC machines were built in the 1940s and 1950s. The standard G-code language was created as a CNC programming language and to standardize all CNC machines. Besides, CAD came into its own and started rapidly replacing paper drawings and draftsmen during the year. After that, with this new technology, CNC took off and began steadily displacing older technologies such as hydraulic tracers and manual machining.

-

1976

Revolution of Woodworking Industry

As with other machine tools, CNC technology was applied to router cutting machines in 1976. Onsrud family, again, invented a machine that revolutionized the woodworking industry. Charles Onsrud patented the “Inverted Router” which more concentrate on the safety and usability. It becomes known everywhere because of its ability and advantages. CNC router machines have flexibility to rout diverse shapes in 2D and 3D shapes based on a set of instructions that were programmed into the machine’s numerical control.

-

2016

Present

Now, CNC router machines typically use the operator’s personal computer to create the shapes to be cut and control the cutting machine. So, everyone can design their own shape although in complex shape such as intricate curves, inside cuts, and sharp corners. The resulting shapes are smoother than a manual milling or handheld router.